Small or Large Series: Unmatched Production Capacity

Discover our Made-in-France candle manufacturing plants offering flexible and responsive production.

BLF Private Label relies on a diverse industrial setup to assist brands in developing custom candles or diffusers. Candles, sprays, scented bouquets, car diffusers… Discover how our tailor-made production capacity adapts to each project, from prototype to large series.

Two candle production sites in France

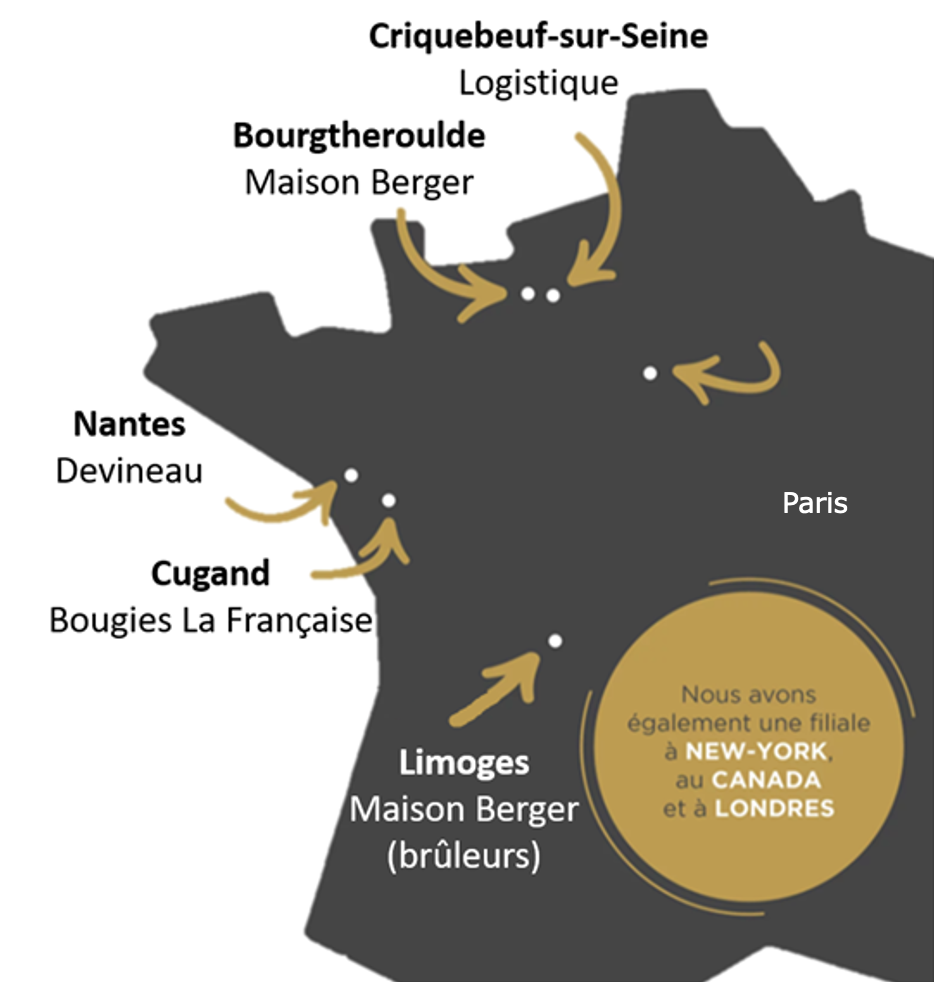

With two candle production sites in France — Cugand (Vendée) and Carquefou (Loire-Atlantique) — BLF Private Label offers its clients a fully integrated industrial tool designed to provide responsiveness, flexibility, and consistent quality.

- The Cugand site, the historic birthplace of Bougies la Française, is dedicated to high-end products and small series that require a high degree of customization.

- The Carquefou site focuses on the production of large series of scented or decorative candles, using automated and semi-automated lines, perfectly suited to the needs of growing brands or international launches.

These two complementary candle production sites are available to clients year-round based on their needs.

A production site specializing in scented bouquets, sprays, and car diffusers

Scented Bouquets

Produced in our factory with a high-performance dedicated machine, our scented bouquets benefit from an optimized impregnation process for controlled diffusion, long-lasting performance, and a refined presentation tailored to the premium segment.

Sprays

Our liquid lines ensure quick and precise filling, ensuring perfect homogeneity of the scented formulas. All our sprays are developed with a high level of care in terms of container-fragrance compatibility, safety, and compliance.

Car Diffusers

Incorporating ceramics shaped in Limoges, our car diffusers reflect a crafted and high-end approach. Their production follows a controlled and reproducible process, combining aesthetics, functionality, and originality.

A rare adaptability in the market

BLF Private Label does not settle for just an efficient tool: the company offers a rare level of flexibility in the contract manufacturing world. Each project benefits from a tailor-made configuration, based on the client’s objectives:

- Industrial series with short lead times and controlled volumes

- Limited series or market tests with a minimum of 1,000 units

- Turnkey solutions, with container selection from stock and rapid customization

- Partial shaping for brands that already have their components (fragrance, container, packaging)

Candle manufacturer since 1902

Candle manufacturer since 1902